8:42 a.m. A familiar ping: “We need to change the ingredients line and add a promo badge. Can we just sticker it?” You’re mid-launch, the warehouse is full, and the seconds feel louder than usual. You want to avoid waste – and you don’t want a fix that looks patched.

So here’s the play: use an over-label for small, safe changes; choose a reprint when structure or compliance shifts. Quick decision. Production-savvy. No drama.

Where Over-Labels Win (and Where They Don’t)

They win when the base is right: dieline fits, color is on target, and the update is small (copy, claim, barcode nudge, promo). They fail when asked to hide bigger problems – wrong size, poor contrast, missing legal, or a full design change. That’s how “cheap” becomes two projects: alignment fuss, scan issues, and a visible patch that chips away at trust.

Also, cost isn’t just material. It’s line time, extra QC, and the risk of a pack that won’t scan. A clear decision protects budget and reputation.

A Simple Two-Bucket Rule

Safe to over-label when:

- The change is localized (a claim, price badge, small translation).

- The surface is smooth: laminated carton, varnished label, glass/plastic. If it’s textured, we test adhesion first. For substrates/finishes, see Materials & finishes that do the selling for you.

- Contrast and codes stay reliable. If the barcode moves, keep quiet zones and finishes consistent; details in Barcodes, legal & nutrition compliance – without killing your design.

- Color remains predictable. If you’re covering metallic or clear areas, add a white underprint so the sticker color matches the panel – White Ink on Clear & Metallic: Build It Right, Proof It Once.

Reprint – don’t patch – when:

- Size, dieline, or panel split changes. Fresh layout is cleaner and often cheaper. Dielines & bleed: the simple guide to packaging that prints right the first time.

- Brand color is drifting pack-to-pack. A near-match sticker is worse than a controlled press run. CMYK vs RGB: why your colors look different in print.

- Regulatory copy changes broadly (INCI order, nutrition table, warnings).

- You’re updating the system, not a single SKU. Fix the master and roll it out – Designing a packaging family: a simple SKU architecture.

If You Sticker, Make It Invisible

- Finish match: glossy on glossy; matte on matte.

- Edge control: micro-radius corners resist lift.

- Coverage: extend 1–2 mm beyond the old element so nothing peeks.

- Color proofing: quick drawdown on the actual substrate.

- File setup: a tidy 3-page PDF – Page 1 art+dielines with overprint spot strokes; Page 2 art-only; Page 3 diecut-only for the kiss-cut. Need a refresher? Dielines & bleed. For repeatable results across variants, templates help – see Reprint-ready templates: cut prepress time by 30%.

Operational Sanity (The Boring Bits That Save You)

- Pick & pack: rolls clearly marked by SKU with a placement diagram.

- QC on the line: first-off approval; barcode scans from three angles under store lighting.

- Record it: drop the spec in your online brand book (WordPress/Elementor on your server) so no one improvises next time – Why your brand needs an online brand book.

Ethical note: This is production guidance, not legal advice. Confirm local regulations and retailer requirements before release.

Short-Term Wins (This Week)

- Salvage good stock instead of pulping it.

- Hit promo windows without waiting for full reprints.

- Keep finance calm with a predictable, targeted spend.

- Trust a substrate-correct prototype – not a guessy PDF.

Long-Term Wins (This Quarter/Year)

- A simple playbook your team can reuse – less debate, faster approvals.

- Cleaner SKU management: stickers for tweaks; reprints for system updates.

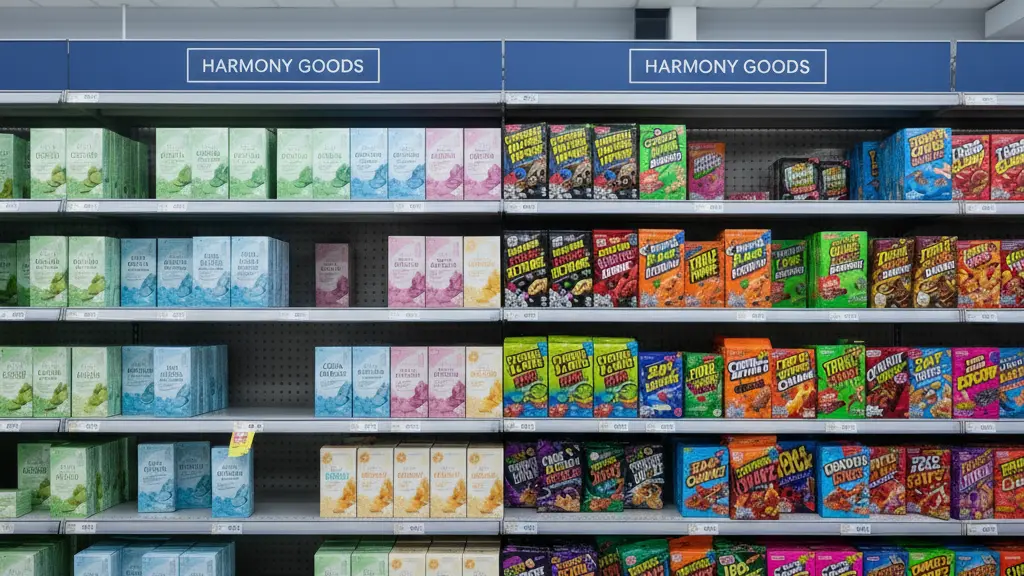

- Fewer “obvious sticker” moments on shelf.

- Stronger foundations for the next refresh – then modernize the whole system. Why a packaging system is better than one-off designs.

How I Handle It (Hungary + In-House)

We start with a quick 10-minute triage: change scope, stock on hand, timeline, substrate. I recommend over-label or reprint, explain cost–risk trade-offs, and – if a sticker is right – produce an in-house prototype on the actual material so you can check adhesion, color, and barcode scans the same day. Files ship as a clean 3-page PDF, and the spec goes into your online brand book (HU/EN) so ops can repeat it without me. Want the smooth cadence? Central Europe, real-time: why a Hungary-based designer makes life easier.

Final Thought

Over-labels are a scalpel, not a hammer. Use them for precise fixes. Reprint when the system needs love. Save the budget – protect the brand.

Need a quick call?

Book a Template Setup & Preflight

I’ll convert one SKU into a reusable master and ship your 3-page PDF hand-off this week.